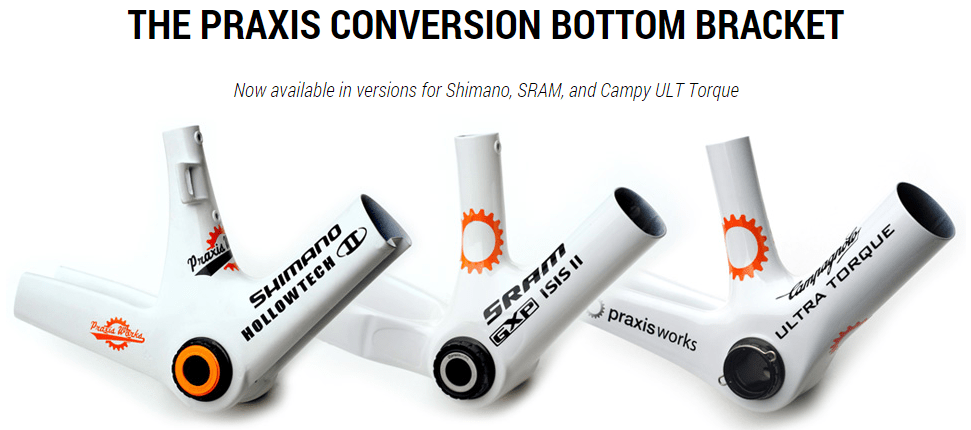

PRAXIS CONVERSION BOTTOM BRACKET Review

-

Our rating

Summary

Great solution used when running Shimano Cranks in a BB30-style bottom bracket shell.

Price MSRP: 2 bearing-based solutions offered

✓ $$ standard steel bearings (check here)

✓ $195.00 hybrid-ceramic bearings

Weight: 138 g (4-7/8 oz), including TPS ceramic bearings

Source: Bike shops, Websites

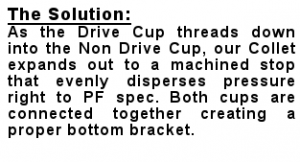

Features: Cup & Collet integrated design solves the problem of press-fit cups working loose

Other Products: Cranks, Chainrings, Conversion & Standard BB’s, Spare Parts & Tools

Pros

- Very well thought out and very well engineered collet style bottom bracket.

- High quality machining and fabrication.

- Fits snug and tight, no working loose.

- Great website support, lots of great how-to installation manuals and videos.

Cons

- In order to keep the costs down for this well-engineered conversion bottom bracket, Praxis has gone with (at least with this BB) Enduro 2437 bearings. Through observation, experience, discussions with mechanics, professional mechanical engineers (ME’s) and PhD mechanical engineering university professors, the 2437 might not be the best choice.

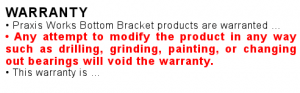

- If you replace the installed 2437 bearings with standard 6805 bearings, you void the warranty!

This means that when you need new bearings, you need to send the whole thing back to Praxis.

— PART 1 —

product to test. In this case, the tester is not beholding to the manufacturer. I bought this bottom bracket through my own funds and will share an honest review of my thoughts and experiences.

product to test. In this case, the tester is not beholding to the manufacturer. I bought this bottom bracket through my own funds and will share an honest review of my thoughts and experiences.

INITIAL OBSERVATIONS

To make this selection even more complicated, frame manufacturers have been known to change their BB standards half-way through a model year run which might cause any Bottom Bracket, including Praxis to be a ‘non-fit.’

For example, frame manufacturers might make an engineering change such as using a customized aluminum shell with a machined lip instead of the spec BB30 C-clips, or even switching over to a BB360EVO from BB30 or PF30.

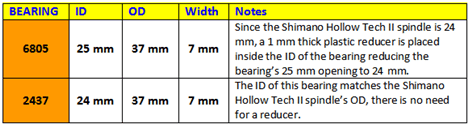

For the SHIMANO Hollowtech II solution, you will need to first decide on which bearings you want as there are two options, (1) an $85 set of steel bearings or (2) a $195 set of hybrid-ceramic bearings. Currently, all Hollowtech II solutions come with 2437 bearings sourced from different suppliers. No industry standard 6805 bearings are available from Praxis and if you choose to swap out the 2437 bearings for the 6805 bearings, you WILL void the warranty.

Praxis is thinking?

Praxis is thinking?

BACKSTORY

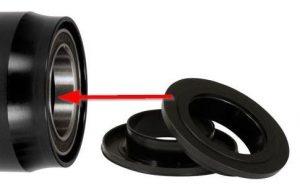

and immediately noticed that there was no plastic reducer sleeve that is usually seen in every other 24mm BB solution. This sleeve is usually required to reduce the 25mm ID of the 6805 bearing to 24mm so that any 24mm crank (i.e., Shimano) will fit. Instead, the Praxis BB was supplied with a set of Enduro 2437 bearings. So, before installing the BB, I decided to do a little research. This is where things got a little complicated.

and immediately noticed that there was no plastic reducer sleeve that is usually seen in every other 24mm BB solution. This sleeve is usually required to reduce the 25mm ID of the 6805 bearing to 24mm so that any 24mm crank (i.e., Shimano) will fit. Instead, the Praxis BB was supplied with a set of Enduro 2437 bearings. So, before installing the BB, I decided to do a little research. This is where things got a little complicated.

DISCUSSIONS WITH MANY

“It turns out that the first 6 words in the question above

are the critical key to ultimately arriving at the answer.”

teams use these exact BB’s with no issue and if these BB’s are good enough for a pro team then they are good enough for the average rider. He also stated that he remembers only 2 BB’s ever returned for warranty issues.

teams use these exact BB’s with no issue and if these BB’s are good enough for a pro team then they are good enough for the average rider. He also stated that he remembers only 2 BB’s ever returned for warranty issues.

INTERFERENCE FIT or PLASTIC SHIM?

consults for Specialized!

consults for Specialized!(metal-to-metal contact) is best, BUT,

that it also depends upon the application.

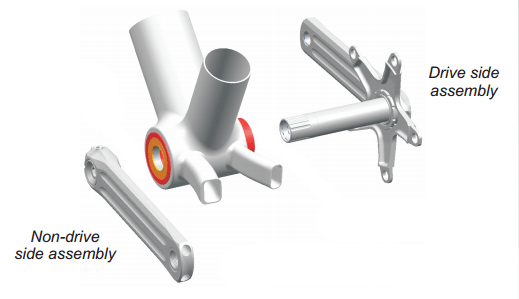

the picture to the right, to assemble a bottom bracket built to the same net-zero tolerance spec as industrial motors, you would need to heat up the drive-side bearing while cooling the crank spindle. Slide the bearing over the spindle, then do the same for the non-drive side. For this season, there would be no issue. For next season, there would be a problem. To disassemble, you would start by removing the left (non-drive side) crank arm, but now what would you do? How would you get the right (drive-side) crank arm off? Remember, the non-drive side bearing is locked onto the crank spindle. A bearing puller won’t work because the bearing is set into the BB shell so there is nothing for the puller to grip onto. Heating up the bearing isn’t an option since you would destroy the carbon fiber.

the picture to the right, to assemble a bottom bracket built to the same net-zero tolerance spec as industrial motors, you would need to heat up the drive-side bearing while cooling the crank spindle. Slide the bearing over the spindle, then do the same for the non-drive side. For this season, there would be no issue. For next season, there would be a problem. To disassemble, you would start by removing the left (non-drive side) crank arm, but now what would you do? How would you get the right (drive-side) crank arm off? Remember, the non-drive side bearing is locked onto the crank spindle. A bearing puller won’t work because the bearing is set into the BB shell so there is nothing for the puller to grip onto. Heating up the bearing isn’t an option since you would destroy the carbon fiber.

SO WHAT’S THE BEST SOLUTION?

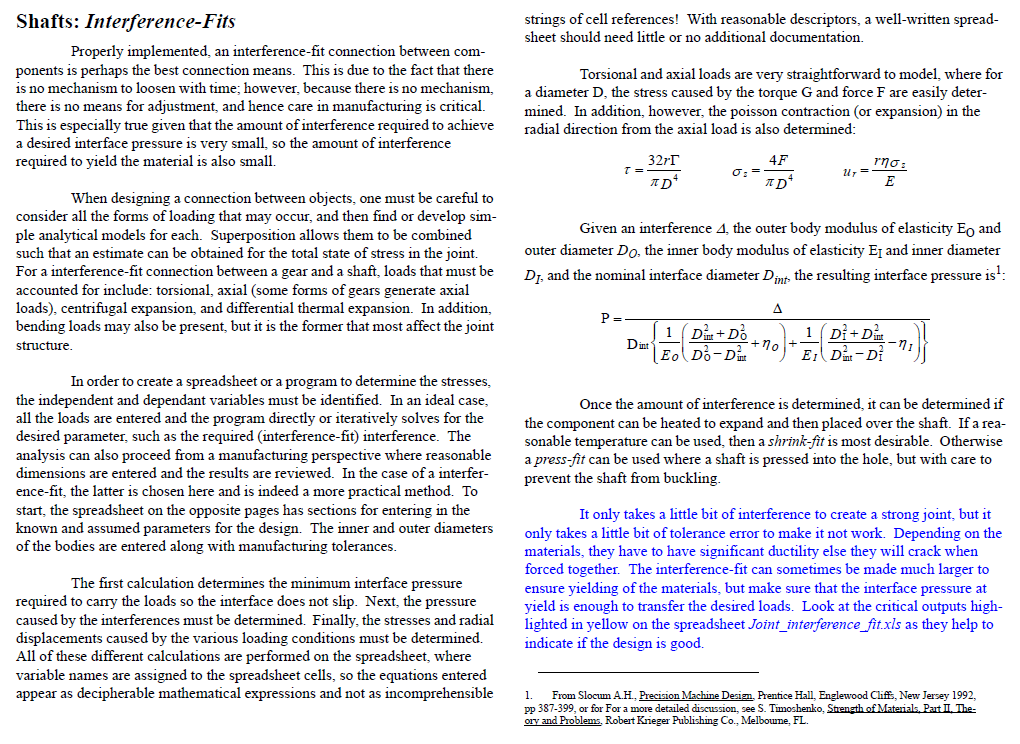

(for an in-depth analysis [From Slocum A.H., Precision Machine Design, Prentice Hall, Englewood Cliffs, New Jersey 1992, pp 387-399], see excerpt from Professor Slocum’s book and class notes at the end of this review)

Cliffs, New Jersey 1992, pp 387-399], see excerpt from Professor Slocum’s book and class notes at the end of this review)

- PLASTIC REDUCER SHIM/DUST COVER (Shimano solution)

- PROs

- Can build to slightly looser tolerance since the plastic shim will ‘take up the slack’

- Inexpensive piece that protects the crank spindle and bearings

- No mechanical difference when compared to metal-to-metal contact

- Eliminates virtually all squeaking between crank spindle and bearing

- CONs

- Some aftermarket replacement plastic shims are made from a cheap brittle plastic and will crack when being reinserted into a bearing

- PROs

- METAL-TO-METAL CONTACT

- PROs

- A very reliable and rigid connection when done correctly, but also with the correct application

- CONs

- The key phrase is “when done correctly.” Even though you will get a very reliable and rigid connection – after heating up the bearing and cooling the crank spindle, you would never be able to remove the crank in a bicycle bottom bracket application

- If BB bearing seizes, friction with metal-on-metal contact, while continuing to pedal, will overheat the crank spindle destroying its heat treating, and possibly ruin the crank – I’ve seen this on a customers bike

- Increased manufacturing time (i.e., increased cost) is needed to guarantee a precision interface, but still needs to be a looser fit between the bearing and crank spindle interface

- To prevent too high of a stress, the typical interference needs to be fairly small, nullifying most of the advantages of this solution. Problems include;

- Radial or circumferential stresses

- Buckling while pressing crank spindle into the bearing

- Clearance of the bearing can be exceeded forcing the balls to jam into the races

- If interface between crank spindle and bearing fit is too loose, crank might feel like it is wobbling or slipping

- PROs

PART 1 SUMMARY

I want to again give a big thank you to Dr. Slocum for providing the overall engineering analysis for this review.

I have always enjoyed bicycling and, through a series of coincidences, became a Bicycle Industry Consultant and Product Tester. I test prototype products for companies and have published only off the shelf production products on biketestreviews.com.