For the past several years, I have been researching and testing greases for use in re-building/re-lubing bike bearings, lubricating cables, nuts & bolts. Below is a recent write up that I completed for an on-line bicycle testing/product evaluation newsletter that discusses this grease as well its testing.

For the past several years, I have been researching and testing greases for use in re-building/re-lubing bike bearings, lubricating cables, nuts & bolts. Below is a recent write up that I completed for an on-line bicycle testing/product evaluation newsletter that discusses this grease as well its testing.

To summarize, this specially formulated grease performs so well that I recently received a reply from Wayne Stetina (Shimano) as to how this grease performs. Even though he cannot officially endorse this product without Shimano Japan certifying and authorizing this grease, he does mention that he prefers it in his own wheels.

This seems to be the thinnest grease you can get before it turns to oil. But that doesn’t seem to negatively impact durability. I have personally inspected Rick’s wheels & can confirm what he tells you about his mileage & wear test results. I can’t personally or officially endorse it before I get approval from Shimano Japan, however I do prefer riding it in my own DA wheels, & have not experienced any wear related failures with this grease or Rick’s Ceramic bearings.

Wayne,

This post might contain affiliate links for which we may make a small commission at no extra cost to you should you make a purchase. Learn more.

The Parts Shoppe (TPS) Performance Bearings & Lubricants

TPS is known for its high quality ceramic bearings and bottom brackets and many top US domestic teams are using TPS products including the 2013 SCOTT Pro Mountainbike Team. TPS’s latest product innovation is a specially formulated extremely low friction grease. After several years of selling bearings, customers (including bicycle shops) wanted to rebuild their ceramic bearings instead of throwing them out. TPS started researching greases and has come up with a winner.

WHATS IN THE PACKAGE:

SBG-32™ comes in two sizes;

- 2 oz. – which is usually purchased by consumers, and

- 10 oz. which is usually purchased by mechanics.

SBG-32™ is specially formulated grease derived from the aerospace industry. It is specifically designed for high speed bearings which are sensitive to viscosity. Using a grease with a thick viscosity grease only slows the bearings down which requires the cyclist to pedal harder. One tester even said “Just adding this grease [SBG-32™] gets you as much performance advantage as replacing steel balls with ceramic balls in your bearings! Doing both, there is virtually no rolling resistance”

WHAT MAKES IT WORK?

Greases consist of Base oils and thickeners. Each has its own purpose and viscosity rating.

But first, What is Viscosity? Viscosity is the ratio of the shearing stress to the velocity gradient in a fluid. Or, in simpler terms, it describes a fluid’s resistance to flow. A fluid with a high viscosity (example honey) will flow very slowly, whereas a fluid with a low viscosity (example water) will flow more quickly. The total apparent viscosity is the adding of the base oil and thickener viscosities together.

- Base oil – grease is mostly oil – which is what does the lubricating. 80%-95% of grease consists of oil. SBG-32™ uses synthetic base oil which has a lower coefficient of friction than compared to mineral (non-synthetic) oil. Synthetic oils allow parts to run smoother, cooler, and thereby faster. For example, the molecules that makeup a standard mineral oil are all different sizes. It would be as if you placed footballs, basketballs, volleyballs, and baseballs on a table then ran your hand over the top of them…not too smooth. With synthetic oil, all of the molecules are the same size. It would be like putting all ping pong balls on a table and running your hand over them. Very, very smooth and much less friction. This is the reason that synthetic oils have less friction and therefore run smoother and cooler.

- Thickener – 2%-20% of the composition of grease is the thickener. Greases are classified according to their thickener as well as their consistency. Consistency is represented by the National Lubricating Grease Institute (NLGI) system rated from 000 to 6. The lower the number the lower the viscosity. 000 would be like cooking oil, 2, like peanut butter, and 6 would be like a piece of cheddar cheese). 90% + of grease manufactured use a Lithium-based thickener. SBG-32™ is clay based and thereby non-sticky and very slippery. Most bicycle greases are NLGI 2 – 2.5. SBG-32™ , on the other hand, SBG-32™ is NLGI 1.25-1.5 (about half of the viscosity of standard high-quality bicycle/motorcycle grease).

- Additives – 0%-15% of grease is additives.

SBG-32™ is perfect for bearings. With its light viscosity, low coefficient of friction synthetic base oil, and anti-wear  properties, SBG-32™ is ideal for bicycle bottom bracket bearings and bicycle and motorcycle wheel bearings. SBG-32™ will keep you spinning fast!

properties, SBG-32™ is ideal for bicycle bottom bracket bearings and bicycle and motorcycle wheel bearings. SBG-32™ will keep you spinning fast!

SBG-32™ is perfect for cables and housing. With its light base oil, SBG-32™ can easily penetrate down into and between the individual wires within a cable which will prevent corrosion making the cables last longer. And, because the base oil is synthetic, it makes the cable more slippery which makes for faster and more precise shifting and braking.

SBG-32™ is perfect for nuts, bolts, screws and fasteners. SBG-32™ is waterproof and will more evenly coat and protect against corrosion, rust and oxidation for a longer period of time.

PUTTING IT ALL TOGETHER – SBG-32™ offers energy savings through reduced friction and lower torque, and reduced temperatures in the load zone of rolling element bearings. SBG-32™ is an NLGI 1.25-1.5 grade with ISO VG 32 base oil.

HOW DOES SBG-32™ PERFORM?

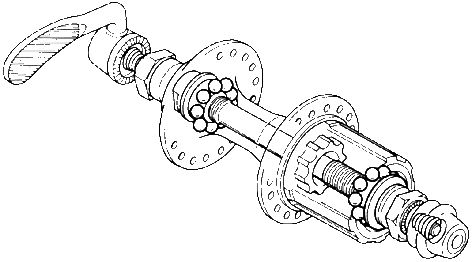

I have 2 sets of wheels. A set of Dura Ace 7850 Carbon Clinchers and a set of Dura Ace 9000 wheels. As of 1/6/2013, the 7850’s have 23,000 miles on them; the 9000’s have 2,100 on them. All miles on these wheelsets have been with TPS Grade 3 Silicon Nitride ceramic balls.

12,000 miles on the 7850’s and 2,100 miles on the 9000’s have been with using SBG-32™.

At 20,000 miles, I took the hubs and freehub body apart to remove the balls for inspection. They looked perfect, no wear, no tear, no chips. I drove to Shimano to pick up a new freehub body and met with my two contacts to show them the condition of the hubs and cones.

My two contacts took one look at the cones and their jaws dropped to the floor. At 20,000 miles, not only were the cups and cones NOT destroyed, the cups and cones did not even have a ‘wear’ ring! All internal hub parts looked as new as if they only had a couple miles on them!

The next day, after applying new SBG-32™ grease, I was literally able to spin the hubs by holding the rim like most people hold the hubs and spin the rim. Yes, there is almost no friction. The following day, I made another trip over to Shimano and had some of their testers ride the wheels around the block. Each one came back with the same facial expression of disbelief that Dura Ace wheels could ride so well. Each one asked me, “What the hell did you do to these wheels? I have never ridden a set of Dura Ace wheels that ride so smoothly and accelerate so quickly…unbelievable!” I told them all I did was replace the stock grade 25 steel balls with grade 3 ceramic balls and replace the OEM stock Klüber Isoflex grease with SBG-32™ grease. Spinning the hubs by hand you could not feel any resistance. The testers ordered some grease to put in their own wheels and I have recently heard back from several that have told me that they are now using SBG-32™ in ALL of their wheels. Again, one tester summed it up by stating “Just adding this grease [SBG-32™] gets you as much performance advantage as replacing steel balls with ceramic balls in your bearings! Doing both, there is virtually no rolling resistance.”

Currently, I am testing the Dura Ace 9000 wheels and a friend is continuing to ride the Dura Ace 7850 wheels. When all is said and done, the rim braking surface will be long worn away before these hubs show any signs of wear. Shimano makes great products and SBG-32™ is there to help.

Recently, I rebuilt the BBRight bottom bracket bearings on my Cervélo R5ca. The stock Enduro bottom bracket

bearings lasted four rides, then they started clicking and clacking. A call into Cervélo yielded “yeah, we’ve had the same issues.” So I replaced them with a set of TPS special order high quality steel bearings. After a season of high mileage and riding in numerous rain storms, the new bearings were starting to click-and-clack. An easy removal using Park Tool’s BBT-30.3, I popped off the seals and scrubbed out the bearings using Simple Green and a toothbrush. After this step, I flushed them with water to remove the degreaser and then I immediately dried them using compressed air. In a clean environment, I packed them with about 40% TPS SBG-32™ grease, and, after cleaning and reinstalling the seals, I pressed them back into the bottom bracket shell using the Park Tool HHP-2 Bearing Cup Press. Replaced the crank and spun…WOW almost like running a full ceramic bottom bracket. This grease definitely works!! Better than advertised!!!

I then re-torqued all of the hex screws on the bike. But first, I unscrewed them all and applied some SBG-32™ grease to all of the threads. Upon reassembly and re-torqueing, I didn’t hear any of that galling squeak. Several months later, I rechecked the torques and each was perfect. A visual inspection revealed that the grease has not dried out. This stuff works great!!!

Several months ago, I replaced the stock Dura Ace cables with NOKON shift and brake cable sets. Even though these cables are stainless steel, I applied a very thin coating of SBG-32™ grease to each cable prior to inserting the cable into its’ housing. A recent inspection shows no rust or oxidation AND the 7900 gro up shifts as smooth as a 7800 group! Some of this is due to the NOKON cable sets, but, using SBG-32™ grease takes shifting to the next level.

up shifts as smooth as a 7800 group! Some of this is due to the NOKON cable sets, but, using SBG-32™ grease takes shifting to the next level.

So, I have used this grease to rebuild wheels, rebuild bottom bracket bearings, re-lube stem and post hex bolts as well

as greasing cables. Others who have used this grease say the same thing. Test marketing the grease at a few LBS’s, they have told me that it flies off the shelf. This stuff works well and is highly recommended!!!

Why not order a 2 oz or 10 oz container of SBG-32™ grease? Everyone needs grease and this is the one to get!

I have always enjoyed bicycling and, through a series of coincidences, became a Bicycle Industry Consultant and Product Tester. I test prototype products for companies and have published only off the shelf production products on biketestreviews.com.