ROAD TUBELESS TIRES: IRC vs. HUTCHINSON

IRC ROADLITE TUBELESS TIRE

Product Tested: 2x new model IRC ROADLITE TUBELESS One FRONT, one REAR

Price: check here

Source: Bike shops, websites

Made In: Japan

Features: Tubeless tire for training and endurance rides. Three colors available (white, black, red)

How obtained: Sample from company

Summary: High-quality 120tpi training tires. Works extremely well as advertised.

HOT!

- Hot abrasion-resistant and cut resistant rubber compound

- Slick tread for increased durability and low rolling resistance

- 120tpi casing

- Butyl coating applied to inner walls for easy adherence of glue patches

- Lease expensive tubeless tire

- 700x23c

NOT!

- 310g-one of the heavier tubeless

- 1,800 miles vs. 2,800 miles for low-cost clincher

- Flat sealant is highly recommended/required

- Even though the least expensive tubeless, still pricey

HUTCHINSON FUSION 3 TUBELESS TIRE INTENSIVE TUBELESS TIRE

Product Tested: FUSION 3 for FRONT (700×23), INTENSIVE for REAR (700×23)

Price: FUSION 3 FRONT: view here

Source: Bike shops, websites

Made In: France

Features: Tubeless tire for racing, training, and endurance rides.

How obtained: Sample from company

Summary: High-quality 120tpi training tires. Works extremely well as advertised.

FUSION 3 HOT!

- Competition Slick profile

- Triple Compound: Excellent compromise between output/grip/longevity

- 127 TPI

- Carbon beads for maximum safety

- Racing

FUSION 3 NOT!

- 290g-Still heavier than clincher, but lightest of tubeless tested

- Still pricey

INTENSIVE HOT!

- Comfort tire

- Thermoplastic Reinforced compound for maximum wear

- Slick competition tread

- Performance 127 tpi casing

- Carbon beads for ride flat safety

INTENSIVE NOT!

- 310g

- Still Pricey

The advertised benefits and claims of tubeless road tires are

- Lower rolling resistance

- Greater flat protection (over rough pavement/gravel roads)

- No pinch flats, no tubes

- Silky Smooth ride

I also measured mileage of these 2 manufacturers’ tires as well as initial installation observations:

I also compared the total cost of a clincher system to that of a tubeless system. See Tables 1, 2, 3 below for an interesting conclusion.

WHATS IN THE PACKAGE:

IRC categorizes the ROADLITE tubeless as “The best tubeless road tire for training and endurance.” The package reads “The highly abrasion resistant rubber compound used in the slick tread increases durability and reduces rolling resistance. The 120tpi casing promises a smooth ride.”

The questions I will be able to answer after wearing the tires out are

- How accurate are these claims?

- How does this tire ride/perform?

- How long did it last?

- Is the tire worth the money?

But first, I need to install them.

INSTALLATION OBSERVATIONS:

For this test, I acquired a brand new set of Shimano Dura Ace 9000 tubeless wheels (WH-9000-C24-TL). Before mounting the IRC tires, I took the hubs completely apart and replaced the grade 25 steel balls with TPS grade 3 Silicon Nitride ceramic balls and using the new TPS SBG-32 ultra-low viscosity grease. I also installed a new Dura Ace 11-28 CS-7900 cassette (since my drivetrain is still DA-7900). All of these are tests in other Biketestreview.com articles.

MOUNTING THE TIRE – Reading the supplied literature, it stated in red, “Do NOT use a tire iron to mount the tubeless tire”. “A tire iron can damage the tire skirt which can prevent the tire from sealing to the rim.”

So, prior to mounting, I took some green dishwashing soap and mixed it with an equal amount of water to make a slippery soapy solution. I rubbed this onto both beads of the tire as well as on the inside of the rim wall. After mounting one side of the tire, I added 1.5 ounces of SLIME PRO.

Then, after adding a little more soapy solution to the tire bead, I started flipping the bead up and over the rim wall using the palms of my hands. As with all tires, I got to about 7/8 of the way then it was too tight to move anymore.

One trick I have learned is to use a rag for grip. The rag not only protected my thumbs but gave me more grip, and, working 1/4“by 1/4”, I was able to pop the final part of the tire up and over the rim wall by hand. On a scale of 1…10 (10 being an impossible effort), I would rate hand-mounting the IRC’s about a 6.5

INFLATING THE TIRE – Using my PARK TOOL floor pump, I gave 3-4 quick pumps and the tire popped onto the rim. I kept pumping and the tire quickly inflated to 105psi. The key is that you need a fairly high volume pump to quickly seal the bead. This is important since there is no tube to capture the air. The air wants to escape by finding the path of least resistance. A high volume pump will usually pop the bead to the inside of the rim wall capturing the air.

I repeated this process for the other wheel and, in about 5 minutes, I had both tires mounted.

Before riding, I let the tires stretch on the rims for 2 days. That way, if I needed to remove a tire, it would be easier removing a tire that was already stretched.

HOW ACCURATE ARE THE CLAIMS?

After 1,800 miles, the rear tire was showing threads. So now is the time to address their claims.

| CLAIMS | ANSWER |

|---|---|

| Lower rolling resistance | YES, these tires felt first |

| Greater Flat protection (over rough pavement/gravel roads) | YES compared to ultra-light clinchers, The Same compared to ‘heavier duty’ standard clinchers |

| No pinch flat, no tubes | YES |

| Silky Smooth ride | YES, smoother than rock-hard clinchers |

These tires rolled very smoothly, much more like a high quality tubular than a rock hard clincher. These tires felt fast and had fairly good flat protection, as good as, if not a little better than a standard good quality clincher. After adding the SLIME, getting a flat was one less thing I had to worry about.

IAS TECHNOLOGY – A SMART IDEA!

For this tire, IRC has added IAS (Internal Air Seal) technology. IAS is a butyl coating to the inner wall of the  Roadlite tubeless tire which (a) helps prevent air-seepage, (b) is an additional level of protection against loss of air due to casing trauma, and most importantly (c) it allows the inside of the tire to be repaired with a glue-type patch kit.

Roadlite tubeless tire which (a) helps prevent air-seepage, (b) is an additional level of protection against loss of air due to casing trauma, and most importantly (c) it allows the inside of the tire to be repaired with a glue-type patch kit.

After my first flat, I kept the slime in for a week to verify that it held. It did, so I unmounted the tire and cleaned up the inside and applied a rubber patch with glue – exactly as if you were repairing a tube. 1,500 miles later the patch was still holding securely. IAS really works.

HOW DOES THE TIRE RIDE/PERFORM? HOW LONG DID THEY LAST?

IRC states that the “ROADLITE Tubeless is specifically developed for training and endurance rides.” Therefore, I would have expected that the center tread section would be fairly hard. What I found was exactly the opposite, the center section was soft and sticky, much like a high performance racing tire. And, for the first 800 miles, this is exactly how it performed and wore but with a disadvantage of carrying 310 grams.

Before each ride, I would check the little round wear indicators and for the first 800 miles, these indicators were disappearing quickly. At 800 miles, I estimated that I would be lucky to get 1,200 miles out of the rear tire. But, from this point forward, the wear slowed greatly – weird. 900 miles, 1,000, 1,100, 1,200 miles, the wear indicators were about the same.

At 1,500 miles, they started disappearing again. 1,600, 1,700 miles, they were now almost gone. I pushed the rear tire to 1,800 miles and finally the threads started showing through the center section. It was time to replace. Of course, your results might vary due to rider weight, road condition, pressure, etc.

The front tire lasted and lasted and lasted. I retired the tire at 3,800 miles, a little over twice the mileage of the rear.

For this test, I did not rotate the tires. Also, for testing consistency, I pumped up the tires to 105psi prior to each ride. With this pressure, the ride quality felt great. 105psi is still within the manufacturers’ limits of 90-115psi.

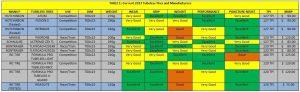

Table 1 shows all (2012) tubeless tires currently manufactured, at least all of the tires I could locate. I took the information from each manufacturer’s website so I could compare tires to each other. The tire I tested is the IRC Roadlite in the blue which shows excellent wear, excellent grip, excellent puncture resistance, very good performance and good weight. The other tires range from pure competition/race to trainers. Tire weights and costs are also shown.

IS THE TIRE WORTH THE MONEY?

There are 3 items to look in in order to determine if these tires are worth the money. These both need to be compared to other tubeless tires as well as clinchers. These are:

- Weight savings

- Ride quality

- Overall costs

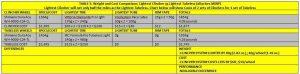

I have researched the tires currently available and have organized my findings in Tables 2 and 3, which show a comparison of cost and weight between tubeless and clincher. (Note: I didn’t include flat prevention products since these were awash in weight and cost). I chose the lightest clincher vs. the lightest tubeless. I also chose Shimano Dura Ace 9000 clincher vs. tubeless.

WEIGHT SAVINGS vs. OVERALL COSTS:

Please look at table 2 and table 3. For table 2, I compared weight and cost by comparing a ‘typical’ clincher to the IRC Roadlite Tubeless. For table 3, I compared the lightest clincher to the lightest tubeless (IRC Formula Pro Tubeless Light). Below is a summary of the data.

| CLINCHER SYSTEM | TUBELESS SYSTEM | |

|---|---|---|

| WEIGHT | 2034g | 2074g |

| COST | $1,533 | ROCK HARD: 6/10 |

| RIDE QUALITY | $1,645 | MORE SUPPLE: 8/10 |

I did a few races on these tires and they rode like they were on rails! Much more secure of a feeling than any of the med-high quality clinchers I have used in the past. Living and riding in SoCal, the roads are usually filled with glass, sharp metal objects and quite a few automobile brake pads, yes, you’ve seen them. I usually train on a cheaper set of med-high quality clinchers due to the high probability of getting a tire sliced with each ride. So, comparing the performance of these tubeless tires to the clinchers I usually use is like comparing night to day. These tubeless are the closest things to a race tire with the added benefits of high mileage and flat protection – two things you won’t normally get with a full racing tire.

So, is the tire worth the money? I would say yes, it is worth purchasing at least a set to try. At around $75 each, they are reasonable priced and the ride is 2x better than a $45 med-high quality clincher tire. So, if you have a tubeless wheel set and if great ride quality and great performance at a ‘fairly’ reasonable cost is what you are looking for, this is the tubeless tire for you.

SUMMARY:

The IRC tires were top quality and very easy to initially mount as well as inflate. I have heard people’s horror stories complaining that no matter what they did, they could not (a) mount the tubeless tire WITHOUT the help of a tire iron – which is strictly forbidden by the tire manufacturers, and, (b) once the tire is mounted, it is impossible to inflate with a floor pump. I was able to easily mount the IRCs by hand as well as inflate with my Park PFP-2.

I was very satisfied with the fit, finish, and performance of these tires…

RATING: 4.5/5

![]()

WHATS IN THE PACKAGE:

Hutchinson categorizes the Fusion 3 as a “VERSATILE TIRE, EXCEPTIONALLY COMFORTABLE and the BEST COMPROMISE BETWEEN GRIP, PERFORMANCE and COMFORT”. The Fusion 3 is considered a Competition tire with a triple compound design. With 127 TPI, this is an excellent tire.

They applaud the Intensive for its DURABILITY, COMFORT and SAFETY. The Intensive also had HARDSKIN technology which doubles the resistance of the sidewalls and quadruples the protection of the tread. The 120tpi casing promises a smooth ride.”

INSTALLATION OBSERVATIONS:

After wearing out the IRCs, I removed the wheels and thoroughly cleaned them. The SLIME cleaned up very quickly and easily. Once the wheels were spotless, I went through the same process as with the IRCs to mount the Hutchinson’s. Both Hutchinson tires were an order of magnitude more difficult to mount.

I finally had to cheat and use a pry tool to get the tires onto the rims. This turned out to be only half of the battle. I added 1.5oz SLIME and attached the floor pump to the valve stem. 25 hard and fast pumps later the bead had still not sealed and the tire was at 0 psi.

I picked up the wheel and worked the tire so that the bead was as close to the edge of the rim as possible. Another 25 pumps, nothing. I pressed down on the tire to try and trap the air, nothing. I tried several other tricks, still, it didn’t seal. I finally had to turn on the air compressor and, using a home-made adapter, I was able to blast in a 100 psi shot of air directly from the compressor and finally, the bead sealed. I guessed I could have accomplished the same thing with a CO2 cartridge, but didn’t want to burn through 2 cartridges just to mount the tires.

I let the tires stretch on the rims for 2 days. That way, if I needed to remove a tire, it might be a little easier.

HOW DOES THE TIRE RIDE/PERFORM? HOW LONG DID THEY LAST?

The Hutchinson’s rode more harshly, more like a hard clincher than the IRC’s, which rode more like a tubular. I also did not feel as secure on the Hutchinson’s cornering at high speed. With the Hutchinson’s, there is a slight wobble from the rear while cornering hard, with the IRC’s, I felt like I was on rails.

This makes sense since, looking at the mileage chart, the Hutchinson’s lasted longer, i.e., harder tread. We really can’t compare the rear tires since the Intensive is billed as a high mileage, non-racing 700×25 tire while the Roadlite is a high performance tire and 700×23.

But, for the front, we can compare apples to apples. The Intensive lasted 11.2% longer than the IRC, but the ride was more like a clincher.

MILEAGE:

To compare the tires, I have summarized the mileage of the tires;

| FRONTS | REARS | |||

|---|---|---|---|---|

| TIRE | IRC ROADLITE | HUTCHINSON FUSION 3 | IRC ROADLITE | HUTCHINSON INTENSIVE |

| MILEAGE | 3,800 miles | 4,235 miles | 1,800 miles | 2,000 miles |

| DIFF | 435 miles | 200 miles | ||

For testing consistency, I pumped up the tires to 105psi prior to each ride. With this pressure, the ride quality felt great. 105psi is still within the manufacturers’ limits of 90-115psi.

One small question came up with the Hutchinson’s. After 900 miles, I measured the tire widths with a dial-caliper. Here are the results. Notice that the even though the Fusion 3 is a 700×23 and the Intensive is a 700×25, after 900 miles, the Fusion 3 was actually wider than the 700×25 Intensive.

| TIRE | TIRE SIZE | MEASURED WIDTH |

|---|---|---|

| HUTCHINSION FUSION 3 | 700×23 | 24.4mm |

| HUTCHINSION INTENSIVE | 700×25 | 23.9mm |

IS THE TIRE WORTH THE MONEY?

Even though the Hutchinson’s lasted 11% longer than the IRC’s, they are 32% more expensive. Couple this with the fact that they don’t have quite the supple ride quality of the IRC’s, my vote goes to the IRC’s.

SUMMARY:

The Hutchinson tires were most difficult to initially mount. I had to cheat and use a plastic tire iron to get the last of the tire over the rim. Mounting by hand, I used all of the tricks, soaping the rim and tire; I still couldn’t pull the last part of the tire over the rim. I even used the towel over the tire trick where you use the towel for additional leverage and I still couldn’t get the tire mounted.

By this time, the SLIME was sloshing all over the workbench so I finally gave in and used a plastic tire lever to get the last part mounted. I had to use the same process for the rear tire as well.

The Hutchinson’s are good tires, but very difficult to mount. The IRC’s have better ride quality and value.

My vote goes to the IRC’s.

RATING: 4/5

Tables 1, 2, 3 shown below. Please click table for full size rendition

Click for full size

Typical Clincher vs. Typical Tubeless

Click for full size

Lightest Clincher vs. Lightest Tubeless

Click for full size

view IRC on Amazon view HUTCHINSON on Amazon

CREDITS:

THANK YOU to Shimano for loaning the wheels, SLIME for Slimepro Tubeless Sealant #10112, and The Parts Shoppe for the ceramic balls and grease.

I have always enjoyed bicycling and, through a series of coincidences, became a Bicycle Industry Consultant and Product Tester. I test prototype products for companies and have published only off the shelf production products on biketestreviews.com.