A Look Inside a ‘Made In the USA’ The Parts Shoppe (TPS) 6806 Bicycle BB30 Bottom Bracket Bearing

As an engineer by trade, I am always looking at best ways to make the bicycle faster. It took about a year, but I was eventually able to find a Chinese bearing manufacturer who produces fairly decent hybrid-ceramic bearings.

Most Chinese companies who claim to be manufacturers are actually just distributors. That’s one of the reasons it took so long to find an actual manufacturer making quality products. But, as I found out, the one drawback was that hybrid-ceramic bearings are quite a bit more expensive than their all-steel counterparts.

I filed the following question in the back of my mind to address later -> “Is there a less expensive steel bearing at the same or better quality than these hybrid-ceramic bearings?”

I ordered several sets of their hybrid-ceramic bearings and started testing. The bearings ran great –  though it took them quite a while to settle in as well as they wore out after 1 season – about 10,000 miles. Still much better than other Chinese bearings that I have worn out and/or broken within 6 weeks.

though it took them quite a while to settle in as well as they wore out after 1 season – about 10,000 miles. Still much better than other Chinese bearings that I have worn out and/or broken within 6 weeks.

After a year of testing these hybrid-ceramic bearings in both bottom bracket and wheel applications, I decided that they were good enough to resell.

Now I had time to research and answer the question that was tucked away.

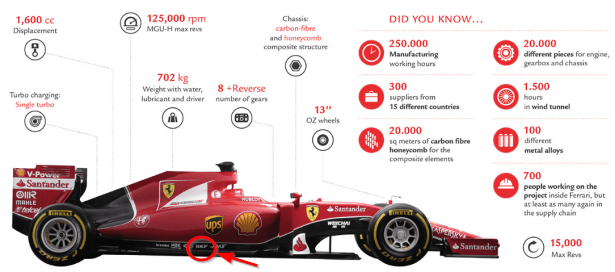

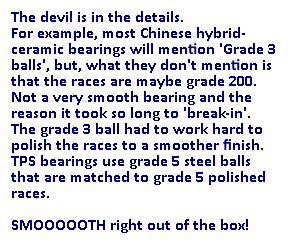

For several months, I looked at all of the top quality bearing manufacturers and found out that SKF makes the best of the best bearings Period. One look through their website s hows that they supply bearings (wheel bearings, suspensions, engine, transmission, clutch bearings) to the Scuderia Ferrari Formula 1 team, Grand Prix teams, NASCAR, MotoGP, Superbike, IndyCar as well as Kart series.

hows that they supply bearings (wheel bearings, suspensions, engine, transmission, clutch bearings) to the Scuderia Ferrari Formula 1 team, Grand Prix teams, NASCAR, MotoGP, Superbike, IndyCar as well as Kart series.

Each bearing meets SKF’s requirements of low friction, smallest size, lightest weight, highest stiffness, high temperature operations, handle high loads, and high speeds. The one problem was cost! Purchasing from SKF, their bearings are fully assembled and certified, as well as a certified HIGH PRICE. In fact, when I first contacted one of their distributors, they told me that ‘my’ price on a SINGLE all-steel 6806 BB30 bearing was $65! There was no way that I could resell certified SKF bearings to the bicycle industry – even if they are the best.

The SKF bearings intrigued me, but how to deal with the high cost? I searched around for several months and finally found a distributor that buys SKF bearing parts…races, balls, ball retainers and seals.

The SKF bearings intrigued me, but how to deal with the high cost? I searched around for several months and finally found a distributor that buys SKF bearing parts…races, balls, ball retainers and seals.

These are the same high quality parts that make up the bearings that SKF assembles, but, buying bearing parts saves money since I am not paying to have SKF assemble and certify them. Perfectly good for bicycle applications. Buying the parts and assembling the bearings myself saves considerable costs which puts them at about the same price as the above mentioned Chinese hybrid-ceramic bearings. The difference is that the TPS bearings roll much smoother right out of the box. The other advantage is that the TPS bearings last much much longer.

So I assembled a pair of TPS 6806 steel bottom bracket bearings (SKF parts and TPS SBG-32 grease) and pressed them into the bottom bracket shell. Since then, I have hammered the bicycle as hard as I could with many all-out intervals on the flats as well as the hills. We do hill intervals on 11-12% grade hills and often generate 1,200 to 1,300 watts for short durations. Bottom line, I didn’t take it easy on these bearings.

This past weekend, I started hearing a clunk, clunk, clunk when pedaling. I thought to myself, sounds like the bottom bracket bearings. Back at the shop, I popped out the bearings and they were definitely worn out. I looked at my testing notes and found out that these bottom bracket bearings have been in the bike for 2-1/2 years which equals about 25,000 miles. That’s A LOT of hard miles on one set of BB bearings.

Disassembling the bearings showed a little galling on the leading edge of th e outer race, about 3 o’clock position. Totally expected since this is where cyclists develop their maximum power during their pedal stroke and is where the bearing is loaded the most. This is actually worse than it sounds since during maximum loading, only 1 ball is pressing against the outer race causing all of the force to be applied to the bearings outer race at one small pin-point.

e outer race, about 3 o’clock position. Totally expected since this is where cyclists develop their maximum power during their pedal stroke and is where the bearing is loaded the most. This is actually worse than it sounds since during maximum loading, only 1 ball is pressing against the outer race causing all of the force to be applied to the bearings outer race at one small pin-point.

Also, I wanted this to be a worst case scenario test so I performed no maintenance on the bearings such as every 6 months popping off the seals, flushing out the old grease and re-greasing. This would have definitely extended their life since the grease was all but dried out which is what led to the galling. Bottom line is that these bearings exceeded my expectations.

Just thought you might want to see what a top quality bearing looks like after 25,000 miles.

I have always enjoyed bicycling and, through a series of coincidences, became a Bicycle Industry Consultant and Product Tester. I test prototype products for companies and have published only off the shelf production products on biketestreviews.com.