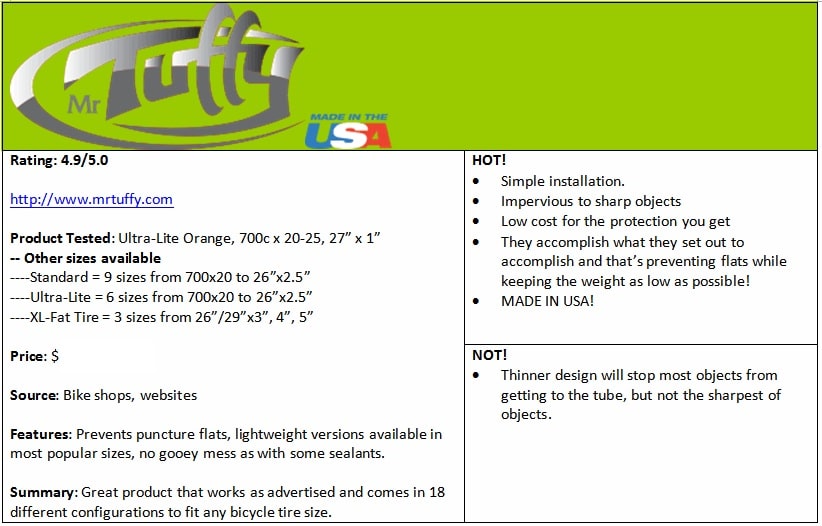

OVERVIEW

Several weeks ago, a month ago, I completed a review of Clean Motion’s RhinoDillos™, in which the review also included an overview of all current flat prevention technologies currently on the market. Please read that review prior to reading this one since this review will concentrate only on the UltraLite Mr. Tuffy’s.

Although the standard Mr. Tuffy’s compares closer to the RhinoDillos™, I wanted to see if a lighter solution makes a difference in road feel as well as flat prevention. Since both of these flat prevention systems utilize a “urethane polymer alloy” material (since the actual material formulas are a secret), I was interested in seeing how one was made lighter.

During my testing of the UltraLites, I had the pleasure in speaking several times with Mr. Ken Hassen, company president, one of the nicest guys you could ever meet. I was able to get an insiders view of his philosophies and the companies products. Here are a few important takeaways from our conversation, (a) Ken conducts continuous R&D, and (b) a tire liners primary goal is to stop flats. Ken continued, “since my products are manufactured right here in the USA, I am able to and constantly do tweak the formulas in an R&D effort to find more puncture resistance at a lower weight and cost.” “And this”, Ken said, “is what differentiates us from the others.” Personally, I like the idea of continual process and materials improvement. Ken also emphasized the fact that a tire liners main function is to prevent flats. “That’s what my customers ask for, better flat prevention … being lightweight is a secondary purpose.” And since Ken is both designer and engineer, he is always working on building a better liner.

SO WHAT IS AN ULTRALITE AND HOW DOES IT COMPARE TO THE STANDARD MR. TUFFY?

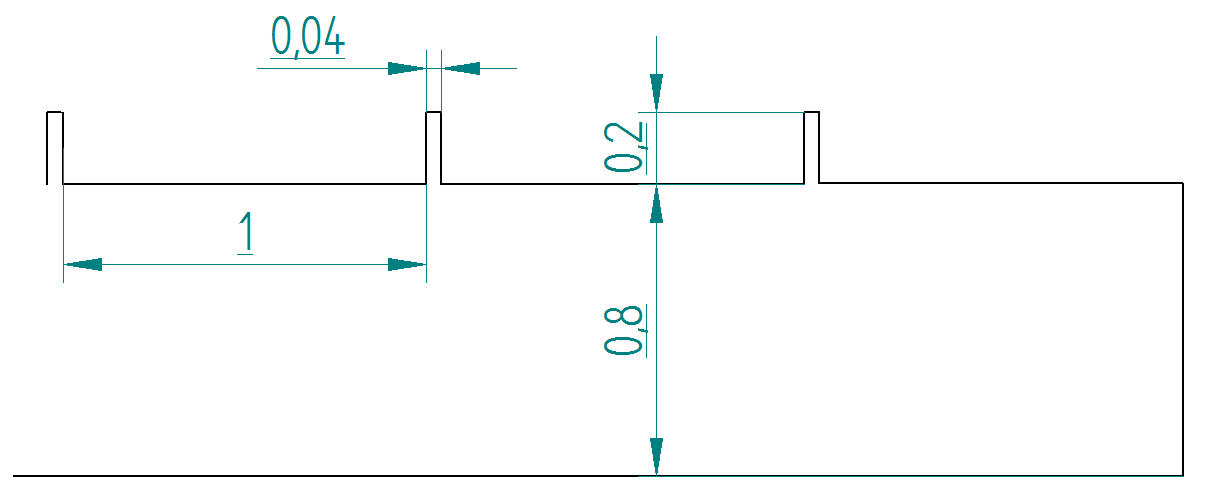

An UltraLite Mr. Tuffy is the same as the Regular model Mr. Tuffy except that the UltraLite has grooves cut into it. This is the only  difference. The regular Mr. Tuffy is a full 1.0 mm thick for the entire liner, while the UltraLite is 1.0 mm thick to the top of the ridges, but only 0.8 mm thick from the base to the groove. As shown above, the edge-view dimensional drawing of an UltraLite shows that 96% of the surface area is 0.8mm thick, while only 4% is a full 1.0mm thick. In contrast, the RhinoDillo is a full 1.2 mm thick.

difference. The regular Mr. Tuffy is a full 1.0 mm thick for the entire liner, while the UltraLite is 1.0 mm thick to the top of the ridges, but only 0.8 mm thick from the base to the groove. As shown above, the edge-view dimensional drawing of an UltraLite shows that 96% of the surface area is 0.8mm thick, while only 4% is a full 1.0mm thick. In contrast, the RhinoDillo is a full 1.2 mm thick.

ASIDE: So why the grooves? As tire liners get thinner, they want to squirm and move around while you are installing them. Often, while inserting the tube (with the liner already installed), the tube will push the liner out the other side. If and when you do get the tube inserted, the liner will look like a snake winding its way left and right, leaving large sections unprotected. The grooves help give the liner stability without adding a weight penalty.

BALANCING ACT

There are five factors that drive the design and manufacturing of high-quality tire liners.

- Material Choice – some materials offer better penetration protection than others, but, they might be heavier and/or more expensive. Example, a urethane at 1.2 mm thick is better at stopping a sharp object from penetrating to the tube than the same urethane at 0.8 mm thick. But, start mixing in other additive chemicals and the physical properties quickly change so that the new material at 0.8 mm thick might be better at stopping a sharp object from penetrating than the original material at 1.2 mm thick, and this is what Ken is experimenting with. Flat prevention is the #1 reason for running a tire liner.

- Weight Issues – the second most important factor is that you want added flat protection with no added weight. But, for increased protection, you normally get the penalty of increased weight.

- Design Issues – a liner that is quick and easy to install.

- Cost Issues – an inexpensive and affordable tire liner

- Long Term Use – a liner that can be used over and over again.

SO WHERE IS THIS BALANCE? Where do you get the best of lightweight and performance?

From what I’ve researched, RhinoDillos and Mr. Tuffy’s are made from polyurethanes. A great material of choice. Urethane applications range from flexible (ex., low density foams, Mr. Tuffy’s), to semi-rigid (ex., packaging foam, coatings, adhesives, synthetic fibers such as Spandex) to rigid hard use products (ex., roller coaster wheels, escalator and skateboard wheels, automotive suspension bushings) where both toughness and durability is required. In fact, it was the introduction of urethane wheels that now allow skateboarders to do all of their tricks.

The RhinoDillos are thick and more rigid, ideal properties that are best used for extreme trails where thorns are a problem.

The RhinoDillos are thick and more rigid, ideal properties that are best used for extreme trails where thorns are a problem.

r. Tuffy Regular Orange is an all-arounder, great general purpose use where glass, small nails, and those annoying metal wires are a problem. The UltraLites are best used in training wheels for a road bike where the roads are fairly clean with the exception of an occasional wire, glass or nail. So the choice is basically left up to your goals and where you ride.

The Mr Tuffy REGULAR is 25% thicker than the UltraLite, while the RhinoDillo is 20% thicker than the Mr Tuffy REGULAR, and a FULL 50% thicker than the UltraLite!

This alone accounts for the differences in weights. But, as described above, material choice is as important as thickness.

INSTALLING MR. TUFFY ULTRALITE TIRE LINERS

I chose the same tires that I used for the RhinoDillos test. Roughly 500 miles on them. Removing the wheels from the bike, I pulled out the RhinoDillos and swapped in the UltraLites. I could feel that the UltraLites were very slippery to  the touch. They also had ridges. Both of these factors makes for an easier installation of the tube, as well as the UltraLite holding its shape during and after installation.

the touch. They also had ridges. Both of these factors makes for an easier installation of the tube, as well as the UltraLite holding its shape during and after installation.

I followed the same process as with the RhinoDillos. I removed the tube, measured, then cut the UltraLites (note: Mr. Tuffy installation page says DO NOT TRIM – but I can’t see leaving an additional 6”+ of liner and the extra weight inside the wheel).

So, I trimmed the liners to include some overlap but not too much. The one thing I did notice was that there was no soft beveled edge as with the RhinoDillos. Since the UltraLites are thinner, maybe the beveled edge isn’t needed?

As I installed the UltraLites into the tire, they slid around easily. Their slippery surface helps when inserting them into the tires, but, they will also want to slide around when installing the tubes. Since the UltraLites are thinner, they are more flexible than the RhinoDillos. On the bright side, though, once installed, it’s going to be a LONG LONG time until you need to change a flat.

Here are several tricks to make for an easy installation.

- Unroll the UltraLites, then roll them back up in the opposite direction. Hold them for about a minute. This will allow them to lay flat making installation easier.

- NOTE: Some may find it easier to install tube first then the liner, others might find it easier to install the liner first then the tube.

- Grab the UltraLite at its center, using this as the starting point by inserting this part into the tire first – insert the center of the UltraLite at the valve stem hole.

- At this point, you have the center of an UltraLite inserted into the tire at the valve stem location with 2 long sections, a left side and a right side still outside of the tire.

- Insert both of these sections into the tire at the same time using your thumbs. Any overlap will occur at the opposite side from the valve stem.

- Now, starting back at the valve stem, re-position the UltraLite so it is centered in the tire.

- If not already installed, insert the tube making sure the UltraLite is centered in tire.

- The tube may try and push the UltraLite out the other side. The solution is to just keep working the tube and the liner an inch at a time … re-centering the UltraLite, then inserting more tube, re-centering the UltraLite, then inserting more tube, re-centering the UltraLite, then inserting more tube, until you’re done.

WOW! I could feel the difference in weight. Removing the RhinoDillos and replacing with the UltraLites, the wheels dropped a total of 31 grams (1.1 oz.) or 15.5 grams (0.55 oz.) per wheel. It doesn’t seem like much, but its all rotating mass. Yes, I could tell a difference with these lighter weight liners.

The wheels felt pretty much like running a slightly heavier road tube. I also experienced a slightly softer and smoother ride compared to the usual rock-hard clincher tire & tube combo. Even at 110 psi, the tires rode as if I had 95 psi. Nice stable comfortable smooth ride. No choppiness, no harshness, no degradation in handling, very secure and stable. All in all, a great road feel.

For flat prevention, how thick of a liner is ‘good enough’ to stop most flats? Although I haven’t gotten a flat yet, I have  run over lots of small pieces of glass, some have actually embedded themselves into the tires. Without the UltraLite, I would have flatted twice since starting this test. The ultimate proof will be when I hit one of those small steel belted radial tire wires.

run over lots of small pieces of glass, some have actually embedded themselves into the tires. Without the UltraLite, I would have flatted twice since starting this test. The ultimate proof will be when I hit one of those small steel belted radial tire wires.

NON-SCIENTIFIC TEST

In the meantime, waiting to run over one of those small pieces of wire, I conducted a non-scientific test comparing the UltraLites to the RhinoDillos to see how much pressure is required to puncture through using an ultra sharp-pointed deck screw.

For this test, I assembled a 3” sample strip of each liner, a piece of colored cardboard, a 2.5 lb. (1.13 kg) Olympic weight, a 5 lb. (2.27 kg) Olympic weight and a very sharply pointed 6×1” deck screw. I chose colored cardboard since it would more easily show any indentations or punctures.

I placed each sample strip of tire liner over the colored cardboard and gently set the 2.5 lb. weight onto the head of the deck screw. I followed it up with the 5 lb. weight. For 3.0 lbs., I estimated. Here are the results.

Now, granted, the screw was as sharp as a pin and there was a direct pressure forcing the screw directly into the liner. In a real-world scenario, the tire would absorb/deflect the object as well as some of pressure. The RhinoDillo stopped the screw from flatting a tube at up to 5.0 lbs. The UltraLite was half of that, but also half the thickness.

SUMMARY

So what does this show?

All 3 liners are made from a very high quality polyurethanes and all 3 are great choices that satisfy their specific requirements. All are reasonably priced from $15 – $18 per set.

The RhinoDillo is the second lightest with the lowest MSRP of $ (check latest price), The Mr. Tuffy UltraLite is the lightest at $ (check price here). The Mr. Tuffy Regular appears to be the heaviest (see chart above) and priced at $ MSRP (check price).

The non-scientific test results are exactly as I would have predicted … A thicker liner will stop a tube-flatting object better than a thinner liner.

But, on the other hand, a thicker liner is much heavier and greatly degrades the performance of the wheels.

In conclusion, all of these liners are top quality and do what they were intended to do very well. You, the cyclist will just need to pick which one will work best for which road condition you will be on most.

YES, I highly recommend the UltraLites!

I have always enjoyed bicycling and, through a series of coincidences, became a Bicycle Industry Consultant and Product Tester. I test prototype products for companies and have published only off the shelf production products on biketestreviews.com.